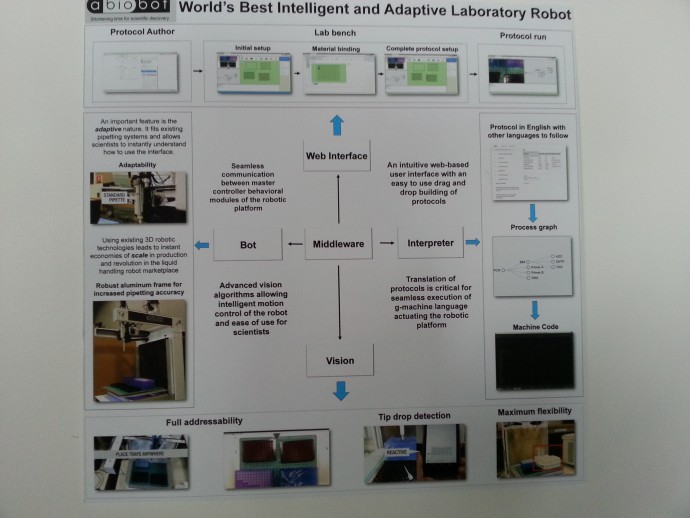

ABioBot is a collaborative project between artists, scientists, and engineers to create a bio robotic lab assistant that automates the processes and procedures of working with biological media, in essence, a liquid handling robot.

The project was funded by a San Francisco Venture Capital firm Indi Bio and the approaches taken successfully brought new funding rounds. Below are the designs and processes I took with the team as the Chief Technology Officer for this project.

We had a dream — a dream of a lab assistant that could eliminate the repetition and errors from bio procedures and protocols so more time would be spent on science and, in my case, art-making using biological media.

We intend to realize a dream with a robotic lab assistant that offers:

- Reproducible science

- Easy use

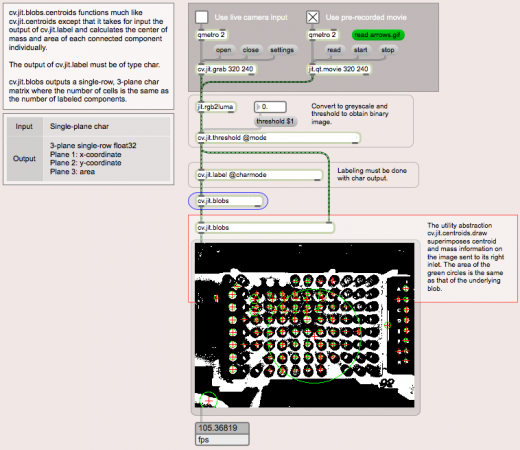

- Vision, sensing, and feedback

- Open hardware, open API

- To do the tedious lab work for you

…so you can get back to the intersections of Art and Science with Biological Media

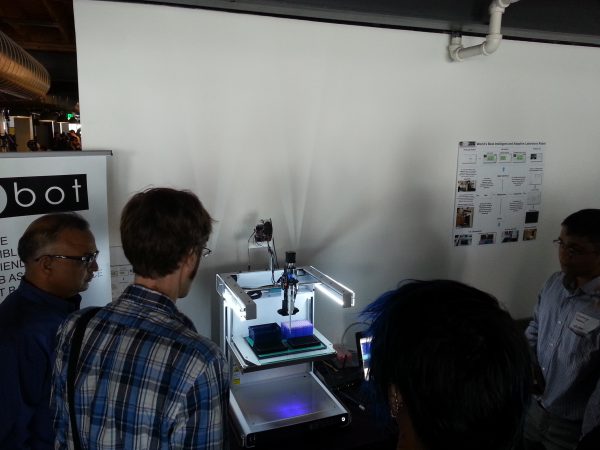

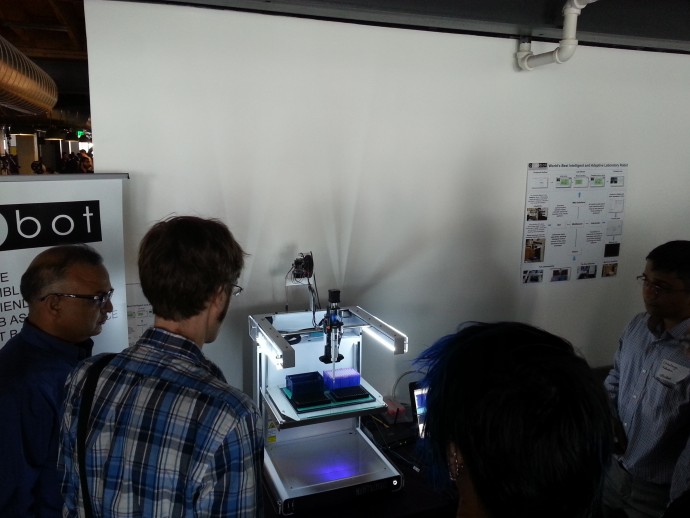

We incubated at the biotech accelerator Indie Bio in San Francisco, CA, with a generous grant to build the prototype.

It has been an exciting adventure combining the unique talents of our team in creating this new product against the backdrop of an accelerator.

Process: Find a stable platform to hack.

As the Chief Technology Office for this project, I chose a Type A Machine (now about of business), a rapid prototyping system that was robust and open-source and would allow me to hack into the system.

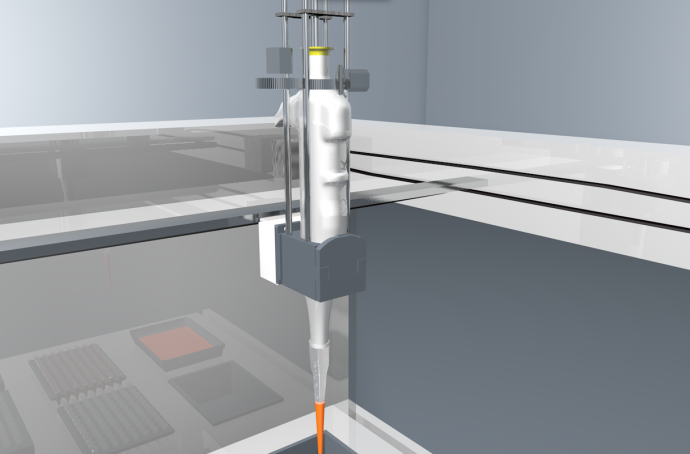

I began by looking at the gantry and how I could directly hack into that to allow the attachment of an Eppendorf.

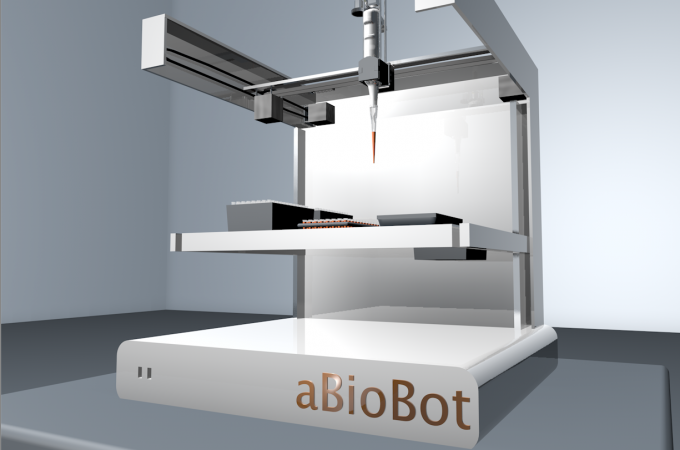

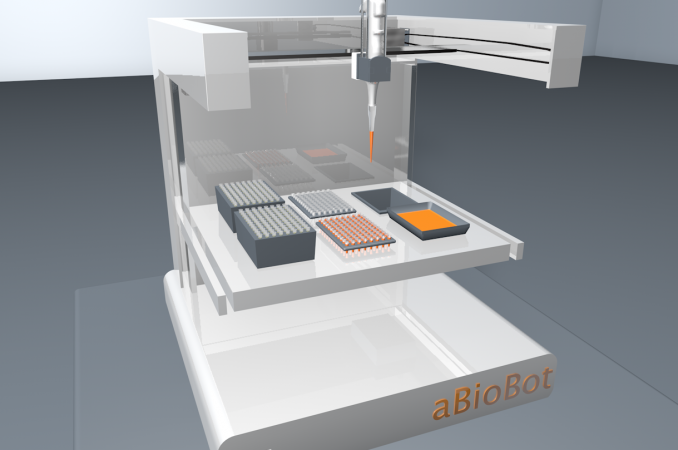

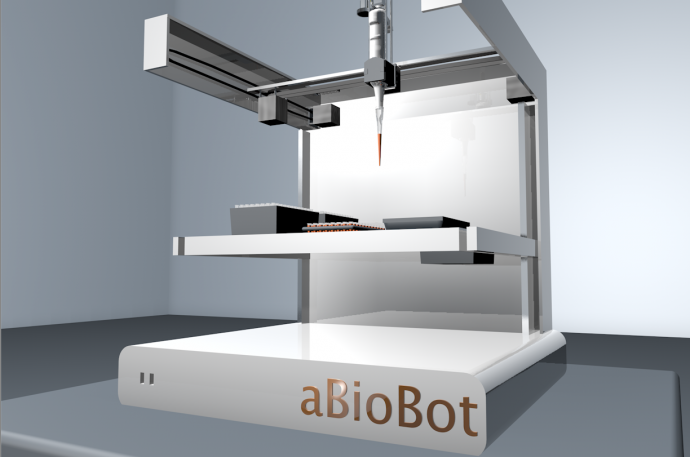

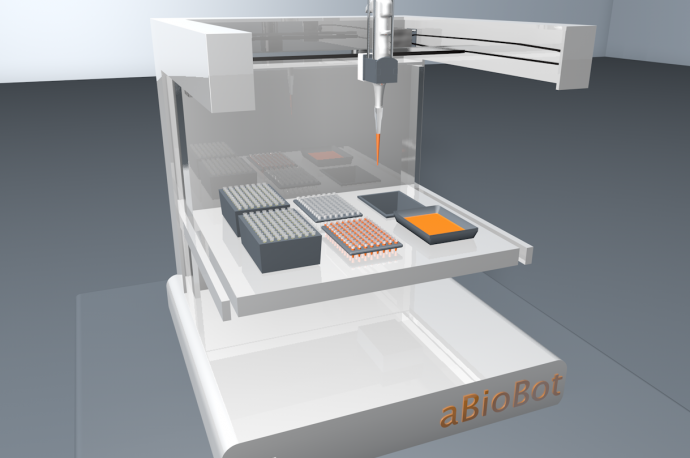

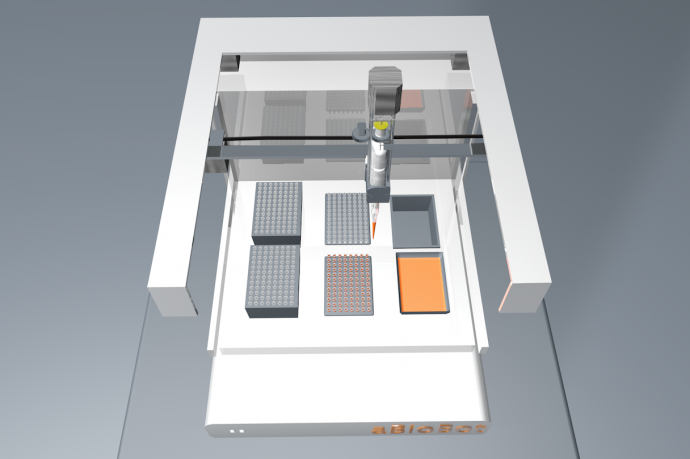

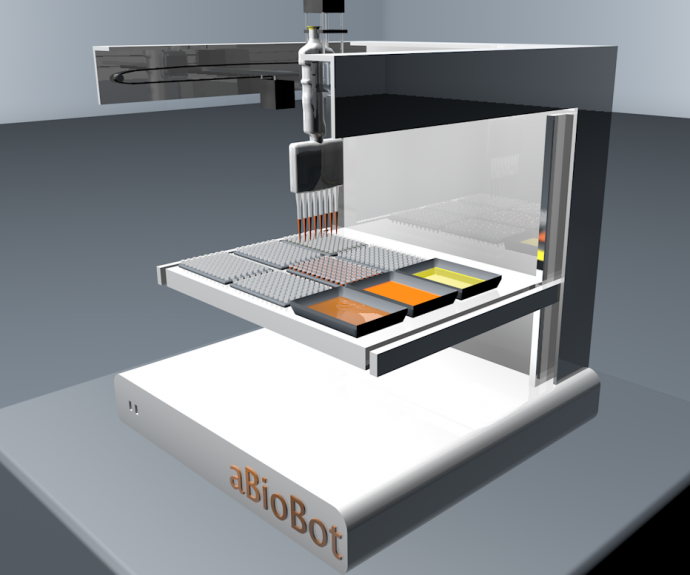

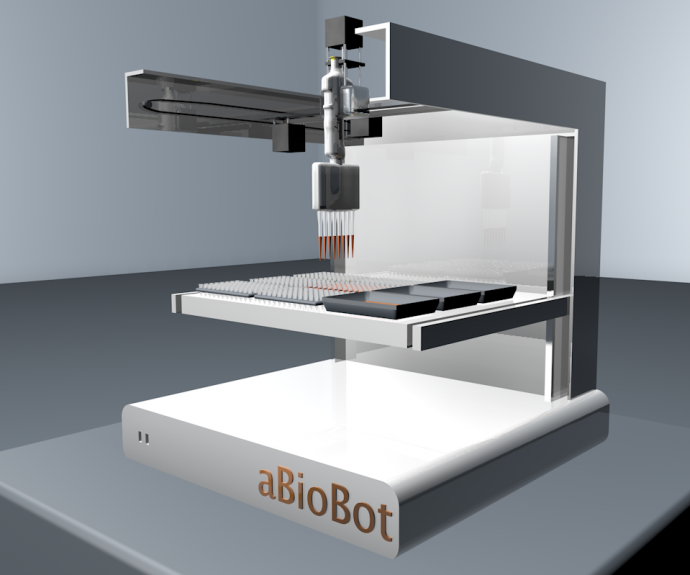

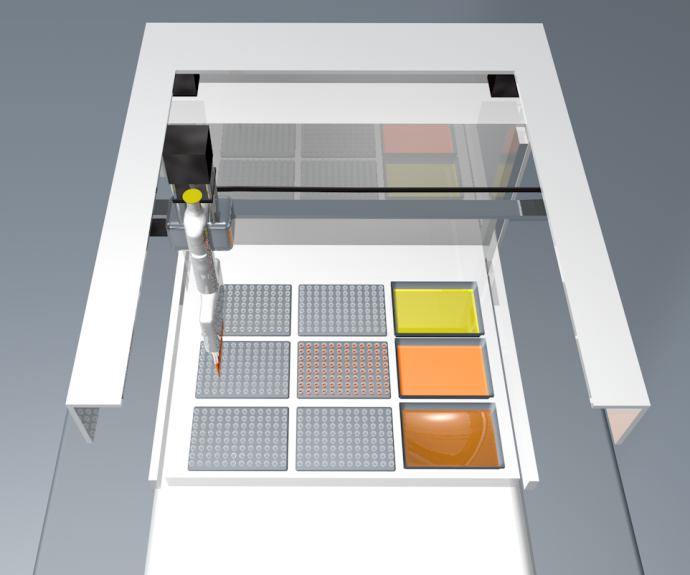

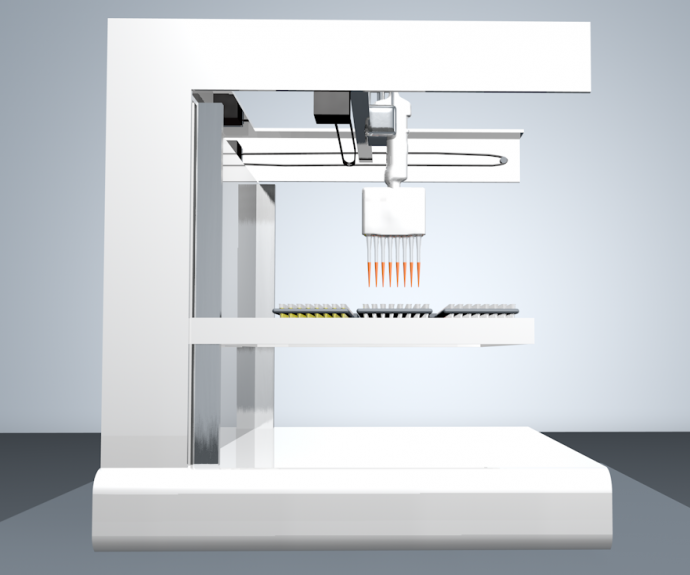

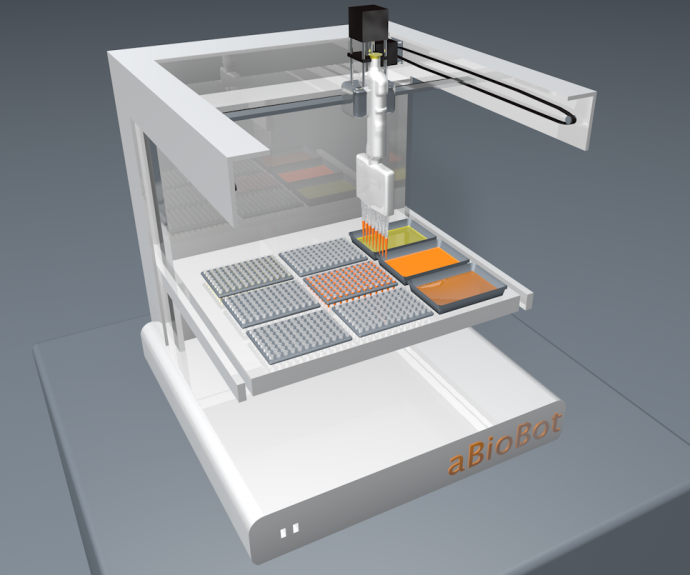

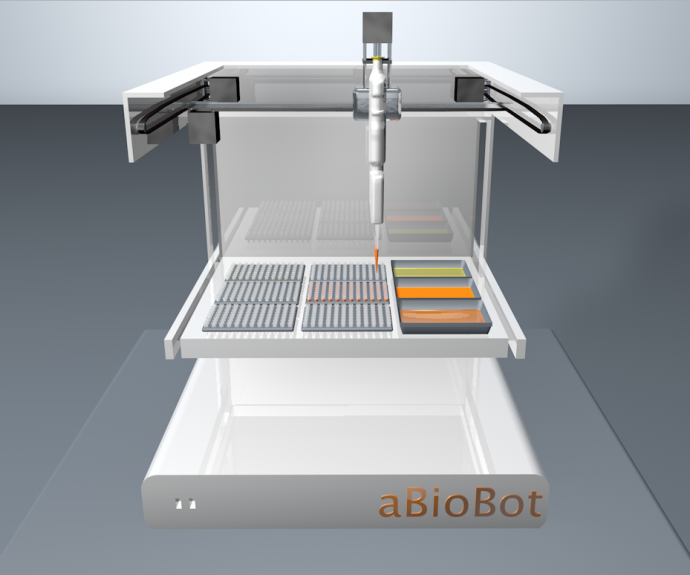

Visuals of how the system was to look were modeled in 3D software Cinema 4D to get a sense of where things would come together.

We exhaustively chronicled commonly used laboratory protocols for automation and building systems and processes that guided us through the design procedures.

These included DNA extraction, the ELISA assay, oligos-based assay library preparation, PCR type experiments (e.g., qRT-PCR)

and assorted assays (cell toxicity, ChIP for protein-DNA binding, Crispr-cas9, GFP tags, Serial dilutions. etc.).

In the process of doing this project, I began to see the challenges of working to create a project funded by Venture Capital, where there was a high expectation of “turning a profit”

Like most artists, I was never focused on money. However, I was focused on making a system that could be sold for under a few thousand dollars to allow an open-source experiment in robotic biological experimentation. With moving more toward a need to “turn a profit,” I lost interest in the company.

Since then, my colleague and friend Dr. Raghu Machiraju have continued the run the company with his wife, Jany Chan. https://www.abiobot.io/

In the updated system, Opentrons has provided the current hardware platforms. Urbanity and Knowable designed AbioBot’s UI and built this website. BigKittyLabs used various software stacks to collaborate with AbioBot and create our UX.

Bigger Tuna developed the lighting platforms required for AbioBot to design Gan.

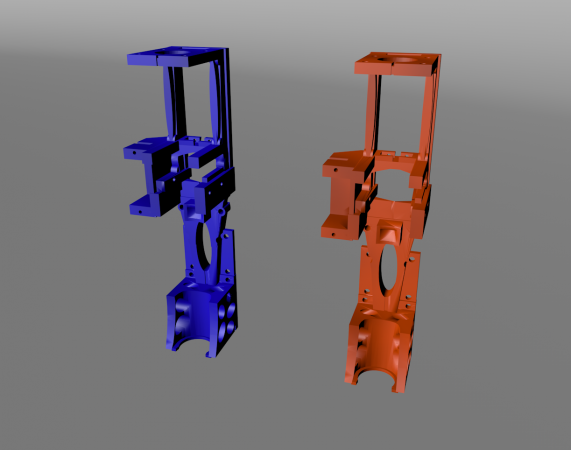

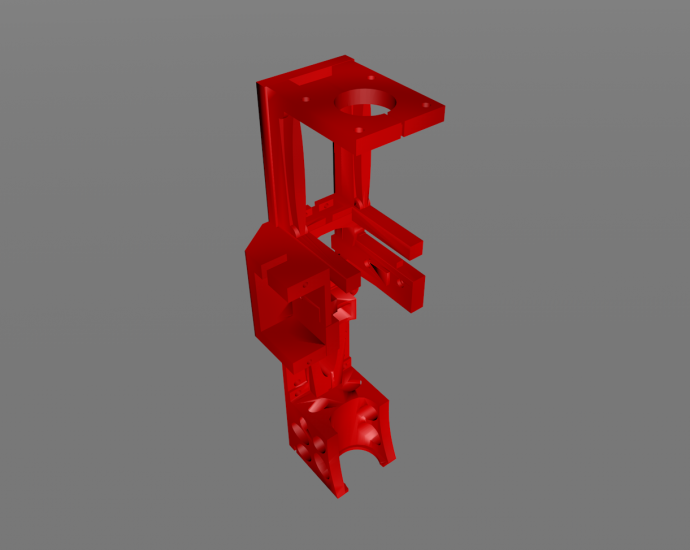

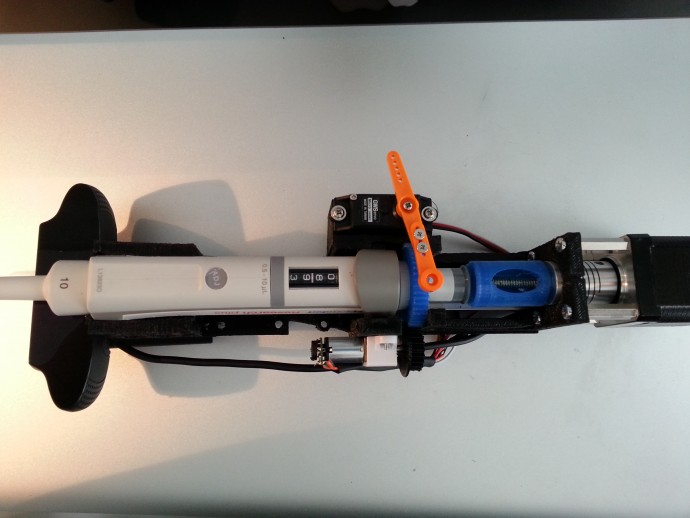

The 3D models below show how I used rapid prototyping to attach a custom fitting element that allowed the attachment of the Eppendorf to the gantry of the existing Type A Machine.

Below is how a camera, Eppendorf, servo motor, DC gearhead motor, and stepper motor are all on the unit and allowed us to dispense micro and measured amounts of liquids.

Below is the demonstration of this prototype which brought an additional 50K in funding to continue developing the project.